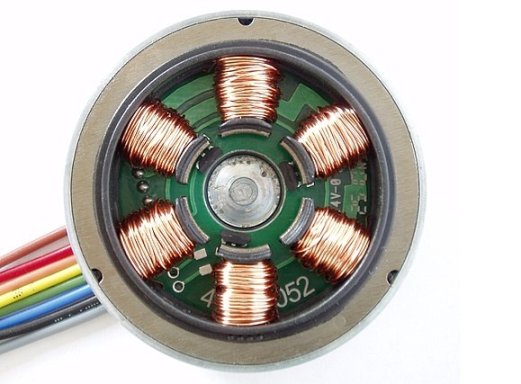

A coil winder is a machine that creates tight and evenly wound coils. These coils are used in electrical devices to produce electricity and power EVs.

To ensure the best results, you need to choose a high-quality programmable coil winder. Here are some features to consider: a. Compatibility with a range of wire sizes.

Table of Contents

Precision

Coils are an essential component in a wide variety of electrical devices and appliances. To function correctly, these coils must be tight and evenly wound. A coil winder is an efficient machine that produces these coils quickly and accurately, allowing for greater productivity. However, like any machine, the coil winder can experience issues at times. The following tips can help prevent these problems and improve the performance of the machine.

When selecting a coil winder, consider the manufacturer’s maintenance requirements and availability of technical support. Also, look for a machine with easy setup procedures and a clear display to help operators understand how to set the required winding parameters. Additionally, a machine that features an automatic wire stripping option may reduce downtime and costs.

Single spindle coil winders can be used to produce a range of coils, including transformers, inductors, solenoids, and other electromagnetic devices. These devices require coils of varying shapes, sizes, and gauges to achieve their unique functions. A high-quality coil winder can ensure that these coils are tightly and evenly wound, reducing the risk of failure in their used device.

These machines can be programmed to perform a series of operations automatically, ensuring that each coil is created correctly and consistently. This can help you save time and money on production, and it will ensure that your products are of high quality. A good coil winder can also be programmed to store multiple programs that can be recalled instantly, reducing the amount of time needed for machine setup for product changeover.

A programmable coil winder can also include an online programming system, a cursor card foot function, and a display that shows the progress of each program. These features can help to avoid errors during the coil production process, which can significantly reduce the quality of your finished product. Additionally, a programmable coil winder can automatically calculate the necessary winding parameters and adjust the laying movement on a real-time basis. This can help you eliminate human error and speed up the production process. Ultimately, a programmable coil winder is an efficient way to create a variety of different types of coils for your electrical and electromagnetic devices.

Efficiency

A single-spindle coil winder is an efficient machine that automates the process of producing different coils. These devices are widely used in various industries, including electronics manufacturing. They can produce a wide range of electromagnetic devices, including transformers, inductors, and solenoids. These machines have many features that help them improve productivity and efficiency.

For example, they can produce a high level of precision in the winding process by automatically correcting the laying movement on a real-time basis. This can help prevent the occurrence of open windings, which can cause conductive bridges in the electromagnet. This is a common issue that can result in device failure. Moreover, single-spindle coil winders can also eliminate the need for manual adjustment of the wire-guiding nozzle on each layer. This can help reduce the guiding errors that can affect the quality of the finished coil.

These machines can also help minimize the contact points between a coil and its stator laminations, reducing the risk of short circuits. This can reduce the overall operating cost of a given device and ensure its safety.

In addition, these devices can also reduce the amount of time required for production by reducing the number of manual steps that need to be performed. This can help to increase productivity and boost profitability.

Coil winding is a critical process in electronic devices, and a single-spindle coil winder can help increase the process’s speed and accuracy. This can result in a higher quality of finished products and reduced maintenance costs.

Single-spindle coil winders can be fitted with a variety of standard PC-based CNC winder controls. These can be programmed to adjust the pitch, traverse length, and Tension at a turn and degree level. This flexibility allows users to customize the coils they produce according to their specific needs.

Additionally, single-spindle coil winders offer a variety of peripheral attachments to accommodate different coils. These include a tailstock, custom tooling, and a programmable tensioner. This versatility makes them an ideal choice for a variety of applications. They can also be equipped with a number of features that make them easy to use, such as an online programming system and a cursor card foot function.

Flexibility

Electrical coils are necessary for a wide range of devices, and they must be tightly wound and evenly distributed to function properly. Otherwise, they could short-circuit or become dangerously hot. Single Spindle Coil Winders can create these coils with more accuracy than manual machines, making them a useful tool for manufacturing companies. These devices can also handle a variety of wire sizes and shapes and can even produce ferrite cores and insulating tapes.

One of the biggest benefits of using a single-spindle coil winder is that it can handle a large number of different wire sizes and gauges. This allows you to create a variety of different products, from simple electrical coils to complex motor coils and power transformers. Additionally, a single-spindle coil machine can often handle multiple spools of wire at once, allowing you to maximize your productivity and output.

Another benefit of using a single-spindle Coil Winder is that it can provide accurate, consistent tension during the coil production process. This helps prevent the wire from stretching or breaking during production, which can lead to quality control issues and reduced efficiency. In addition, a single-spindle machine can help you maintain the proper bobbin and feeder motor speeds to ensure consistent winding.

Finally, a single-spindle winder can also help you eliminate the need for manual adjustments during the production process. This can save you time and money and improve your overall productivity. A single-spindle coil winder can also support a variety of different bobbin and feeder motor types, ensuring that it will work well with your specific application.

Coils are used in a wide range of electrical and mechanical devices, including ignition coils, relays, SMPS coils, and lighting equipment. They are also an essential component of electric vehicles, which have seen rapid growth in the past few years due to growing awareness about climate change and the need for sustainable transportation options. This growth has led to a significant increase in demand for coil winders, which can help manufacturers meet this growing need. The flexibility offered by a single-spindle coil Winder can make the process of creating these coils easier and more efficient, boosting productivity and reducing overall production costs.

Troubleshooting

When the correct amount of tension is not applied to a coil, it can lead to a variety of issues, from tangled wires to damage to the device itself. This is why Single Spindle Coil Winders are equipped with built-in tension control to ensure that the coil is wound properly. This helps to reduce maintenance costs and improve productivity.

Electrical coils are often made with insulated materials that help to conduct the electricity that flows through them. These coils can be used in a number of different applications, including motors, generators, and transformers. Typically, the coils are wrapped around a core that is made from metal or other conductive material. This is then wrapped in a layer of thin, insulating material.

During the coil production process, a certain degree of plastic deformation can occur in the insulated material. This can affect the laying movement of the wire, which can cause problems with the winding quality. Single-spindle coil winders are able to compensate for these problems by using an integrated control unit to calculate the winding parameters and corresponding laying movements on a real-time basis. This helps to ensure that the coil is positioned correctly and produces a high fill factor.

A Single Spindle Coil Winder can also be programmed to allow for a variety of different winding patterns, such as wild or orthocyclic windings. This flexibility makes it easier to meet the unique needs of your application. In addition, these machines can be fitted with a variety of peripheral attachments to enhance their capabilities. These can include a tailstock, custom tooling, and a programmable tensioner.

Single Spindle Coil Winders are an advanced machine that plays a crucial role in the electronics manufacturing process. They can be used to create a wide range of coils, including transformer coils, inductors, and solenoids. These machines can help increase production speed, improve accuracy, and decrease maintenance costs. They can be used in a number of different industries, including automotive, aerospace, and telecommunications.