Construction labours are the mainstay of our society. They build safer roads for us, provide reliable accommodations for our families, and establish offices for us and schools for our children. In general, every building you see has been touched in some way by builders, engineers, and architects who fashion them. The machines used by the constructors are heavy equipment machinery and tools, which are tactful objects to handle, like drilling trucks, boom lifts, scissor lifts, bulldozers, etc. demand a keen observance for their handling. Any slight mistake can result in an emergency situation. Thus for labourers and constructors, safety tips for handling the machines is very essential. Here are some basic safety tips for managing heavy equipment.

Source: Copeland International

(https://www.copelandintl.com/blog/material-handling-equipment/safely-handling-your-heavy-equipment/)

Table of Contents

Train Your Workers

Proper training of the workers is the step to handling machines and tools. Invest in some good training and workshops, and before you put a man in the work field, make sure he has taken a basic safety handling workshop for either some certified institution or from your reliable sources. Make your workers read the Automotive Repair Articles to gain insight regarding their work. Heavy machines are extremely technical, and each machine has its own flukes and attributes. You must understand your equipment and tools before you put your hands on them, otherwise, disasters are bound to happen.

Source: Steadfast Entities

(https://steadfastentities.com/spotlight-on-heavy-equipment-operators/)

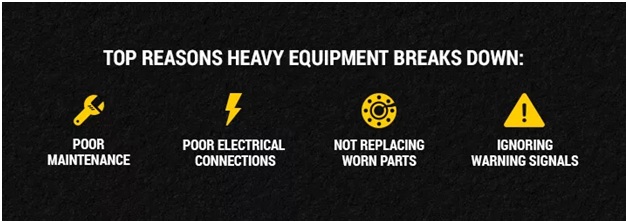

Inspect Your Machines

Make a routine for every labour to check their machines and tools before they start operating them. Every machine is composed of hundreds of small moving parts and thus issues can arise in any part, That is why it is necessary to regularly get service for heavy machinery to ensure the machines are well maintained to causing a major accident. Invest in your machines, and avoid using machines that are not in standard condition. Properly examining your machines and knowing they are up to par is crucial to ensuring safety.

Source: Mac Allister

(https://www.macallister.com/importance-of-equipment-inspections/)

Wear Safety Gears

Working with heavy machines is tough. You not only have to deal with the giants but also have to wear all the safety gear required, to ensure your safety. The safety gears include a seat belt, helmet, gloves, special suiting, etc. If the vehicle rolls, wearing safety gear keeps the operator from being thrown from it and saves one from having severe injuries. Every machine operator should be provided with his own safety gear and should be strictly instructed to use them whenever they are at work.

Source: Slide Team

(https://www.slideteam.net/work-place-poster-with-mandatory-safety-gear.html)

Check the Site

The location conditions vary as well. Some areas are bumpy, some are rocky, and some are muddy. Every area demands a different kind of machine and vehicle thus always check the site where you have to work before you arrange your equipment. In detail, conduct a visual check for overhead and underground dangers, such as cables, gas lines, and hydro wires. Dig with a shovel when underground obstacles are close. Wherever holes are made, set up barriers to avoid workers or visitors to the work site unintentionally falling into them.

Source: Wallpaper Fare

Avoid Blind Spots

It is crucial that heavy equipment operators know if there is no one and nothing behind them before they back up. To avoid blind spots, the operator must physically get out of his machine to check the rare of his motor and confirm that there is nothing behind. Mirrors do not always provide a whole 360-degree scope of vision. The short time it takes to hop off the machine and look may save a life.

Source: CAT Simulators

(https://catsimulators.com/blind-spot-awareness/)

Get On and Off Attentively

Riding a heavy vehicle is not easy. Even getting on a heavy bulldozer or a lifter is itself a job. Many operators have harmed their lives by not paying attention to this step of handling machines, and they just try to jump off, which often is not suggested and is dangerous. Always use the three-point rule; use two hands and one foot or two feet and one hand to mount or dismount safely.

Source: Big Rentz

(https://www.bigrentz.com/blog/3-points-of-contact)

Loading and Unloading

Heavy machinery is quite big, thus everything to be done with it needs extra care and safe handling. Loading and unloading and from heavy equipment is a task to be performed by professional and experienced operators. Many times, a little negligence from the operator’s side while loading or unloading, has resulted in severe problems that have also taken many lives. Make sure your heavy equipment is on level ground. This lessens the chances of the vehicle rolling or sliding. Also, have someone act as a spotter to make sure people are standing away from your loading or unloading area.

Source: India Mart

(https://www.indiamart.com/jjmule-contract/loading-unloading-services.html)

Maintain Communication

Communication plays a vital role in every field and sector. Different machines and heavy equipment are in action on the work-site, to maintain coordination between the operators of these machines, well-gripped communication should be ensured to avoid hazards and increase the work speed. Apart from machine operators, well-to-do communication should also be developed between the ground staff and supervisors. Two-way radios are one of the best ways to do this.

Source: Desk Alerts

(https://www.alert-software.com/blog/workplace-safety-communications)

Obey the Rules

Every worksite has its own rules and regulation, and also every machine comes with a manual that specifies its do’s and don’ts. Always try to follow the rules as they are made to protect the machine and the operator. Know load limits for size and weight for the equipment set up, and also ensure if the load is secured using the correct attachments.