Laser cutting has created quite a buzz in the market. In no time laser cutting in Melbourne has become the most popular cutting method in many industries. Speed, versatility, and high accuracy are the features that give this modern technology an edge over its contemporaries. It allows you to cut almost any material and suits well for many applications from decorative items to architectural designing and cutting of large-format materials.

A wide range of benefits has taken this technology to the pinnacle at lightning speed. Here is all you need to know about this amazing technology that is revolutionizing the cutting and marking processes.

Table of Contents

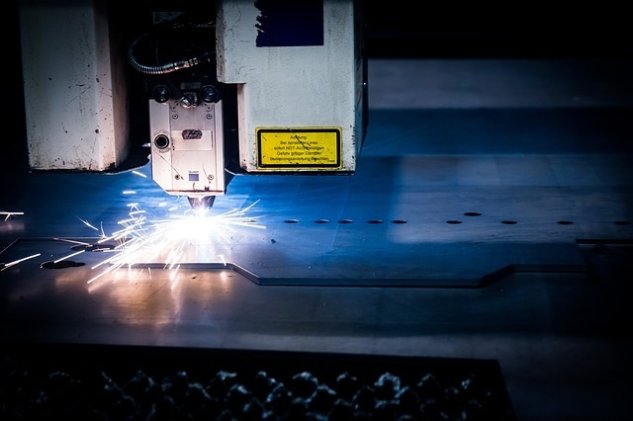

Laser cutting machines

Laser cutting machines have their footprints in history are marked in the early 1950s. However, it took nearly two decades before the technology could find its place in true applications. It entered the manufacturing industry around the 1970s and today has become the most preferred method for cutting metals.

The working of the laser cutting machine is simple. You place the cutting material on the machine and direct the output of a high-power laser onto the material to cut. A computer numerical control allows you to direct the intensity and movement of the laser to ensure perfect cutting. You would need a high-intensity cutter to cut thicker material.

Materials a laser cutter can work with

Laser cutters can be used to cut anything from paper to plastic and wood to textile. You can also use it with materials such as aluminum, red metal, stainless steel, and carbon. These machines are highly versatile and can cut multiple shapes with utmost precision.

You can cut squares, rectangles, rounds, and even uneven shapes using laser cutters. Laser tube machines take the capabilities of laser cutting to new horizons. These machines allow cutting tubes, channels, and structural shapes and make holes and intricate cutout designs.

Benefits of laser cutting

The advancements in laser cutting technology have brought several benefits. The most prominent ones are the enhanced speed and quality of the cuts. These improvements have slashed down the cost for both manufacturers and consumers.

Laser cutters can deliver exactly to the specifications and work with stringent tolerance. This means you do not need any additional machines and efforts for post-processing. You can also merge multiple operations into a single step to further accelerate the process.

Important considerations before diving into laser cutting

Selecting between laser and other cutting methods can be perplexing at times. All the methods are quite effective but their applications differ. Clarity on the type of cutting you need is paramount in picking the best method.

Often, the specifications are not as stringent as mentioned in the project documents. In such cases, plasma or oxy-fuel cutting can be a good choice. However, if the tolerance in the specification is tight, laser cutting is the best technology for the job.

Benefits to the business

Laser technology is highly automated as compared to other cutting methods. It can streamline your processes and optimize production capacity to give your product a competitive edge in the market. With the highly precise technology at hand, you can explore the possibilities of improving functionality and enhancing aesthetics. You can implement advanced processing with tight tolerance and much-reduced cost.